A Sustainable Future for Hydraulic Elevators

Media outlets are consistently reporting on the price increases for fuel. Difficult times such as these have much of North America asking, “how do we work towards petroleum independence?” Companies are vetting their supply chains and wondering how to distance themselves from petroleum.

This rise in cost for gas is just the tip of the iceberg as it relates to the amount of oil that we consume. This is why TK Elevator has set aggressive sustainability goals, including net-zero carbon by 2050, to ensure that we do our part for the planet.

When thinking about transportation methods that utilize heavy amounts of gas with high carbon emissions, you might think of a plane or automobile. Though these examples are accurate, vertical transportation often needs oil to function as well. As we evolve our products, this is a fact that we must consider and take seriously.

TK Elevator and Sustainability

TK Elevator was the first company in the elevator industry to pursue a higher level of transparency regarding the environmental impact of elevators. These efforts began with a Health Product Declaration (HPD) released in 2014.

The HPD is an easy-to-understand document that clearly lays out all of our product information to allow customers to make a fully informed decision. It is designed to help our customers thoroughly understand the 10,000+ parts that make up an elevator system. TK Elevator remains the leader in our industry’s sustainability initiatives with the ecological objectives that we strive towards.

Since these goals have been set and we have put our plans into action towards net-zero carbon, we have taken the initiative to guarantee that our products reflect these efforts. While both our traction and hydraulic elevators have initiatives in place to lower their carbon footprint — our hydraulic application could be the key to moving toward petroleum independence in this ongoing crisis.

Senior Sustainability Manager, Monica Miller Brown recently stated, “We’re proud to continue to provide a quality hydraulic product that makes sense for the low-rise market, without sacrificing finite resources.”

Hydraulic Elevators and Biodegradable Fluid

Hydraulic elevators are ideal for low- to mid-rise buildings and have gained popularity since the technology first debuted in the 1800s. A reliable and sturdy choice, many building owners have opted for this elevator over the traction design due to the lower cost of maintenance and repair.

Though it is trustworthy, one concern for hydraulic applications is the oil that it requires to function. Unlike traction elevators, the hydraulic elevator does not rely on being pulled by steel ropes or belts. Hydraulic elevators operate using a pump that pushes hydraulic fluid into a cylinder that creates pressure to then push a piston which allows the elevator to rise and lower safely.

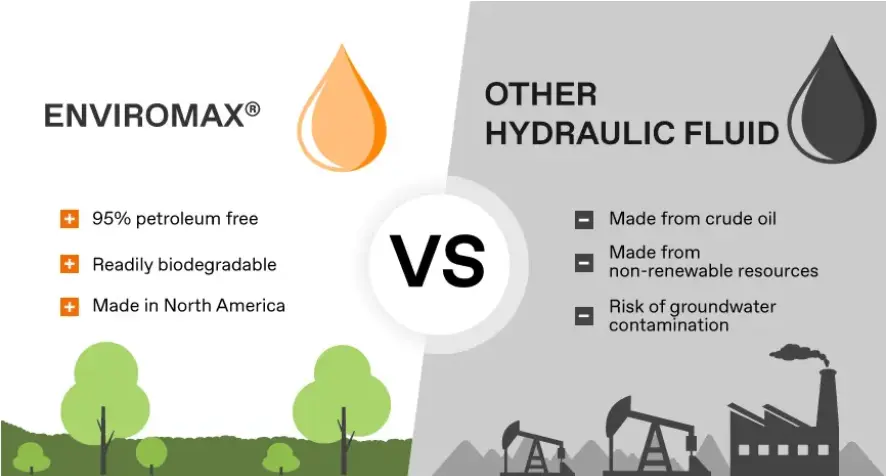

This hydraulic fluid that is needed for the proper function of this elevator was typically petroleum-based. To move away from reliance on a non-renewable resource, TK Elevator has worked towards finding a viable solution.

In partnership with BioBlend Renewable Resources, we released enviromax in 2012: the industry’s first performance-improving, plant-based hydraulic elevator fluid. This is a 100% recyclable and biodegradable solution that works with all hydraulic elevators and takes only one growing season from the canola plant to regenerate.

While we make a way for the future of lowering our petroleum usage in the elevator industry, this alternative to typical oil will benefit our earth greatly while providing a low total cost of ownership. Learn more about TK Elevator’s efforts in sustainability.

United States

United States